I-4-Layer Printed Circuit Board PCB ye-Battery Management Systems

Ulwazi olusisiseko

| Umzekelo No. | PCB-A47 |

| Iphakheji yezothutho | Ukupakishwa kweVacuum |

| Isiqinisekiso | UL, ISO9001&ISO14001,RoHS |

| Isicelo | Ii-elektroniki zabathengi |

| Ubuncinane besithuba/umgca | 0.075mm/3mil |

| Isakhono seMveliso | 50,000 sqm / ngenyanga |

| Ikhowudi ye-HS | 853400900 |

| Imvelaphi | Yenziwe etshayina |

Ingcaciso yeMveliso

FR4 PCB Intshayelelo

I-FR ithetha "i-flame-retardant," i-FR-4 (okanye i-FR4) luphawu lwebakala le-NEMA lwe-glass-reinforced epoxy laminate material, imathiriyeli edityanisiweyo eyenziwe ngelaphu elilukiweyo le-fiberglass kunye ne-epoxy resin binder eyenza ibe yi-substrate efanelekileyo kwizinto zombane. kwibhodi yesiphaluka eprintiweyo.

IiPros and Cons of FR4 PCB

Izinto ze-FR-4 zithandwa kakhulu ngenxa yeempawu zayo ezininzi ezinokuthi zizuze iibhodi zesekethe eziprintiweyo.Ukongeza ekufikeleleni kwaye kulula ukusebenza nayo, sisigqubuthelo sombane esinamandla aphezulu kakhulu e-dielectric.Ngaphezu koko, yomelele, ixhathise ukufuma, ixhathisa ubushushu kwaye ikhaphukhaphu.

I-FR-4 yimathiriyeli efanelekileyo ngokubanzi, ethandwa kakhulu ngenxa yeendleko zayo eziphantsi kunye nokuzinza komatshini kunye nombane.Ngelixa le mathiriyeli ineenzuzo ezibanzi kwaye ifumaneka kwiindidi ezahlukeneyo zobunzima kunye nobukhulu, ayilolona khetho lungcono kwisicelo ngasinye, ngakumbi usetyenziso olusebenza ngamaza amaninzi njengeRF kunye noyilo lwemicrowave.

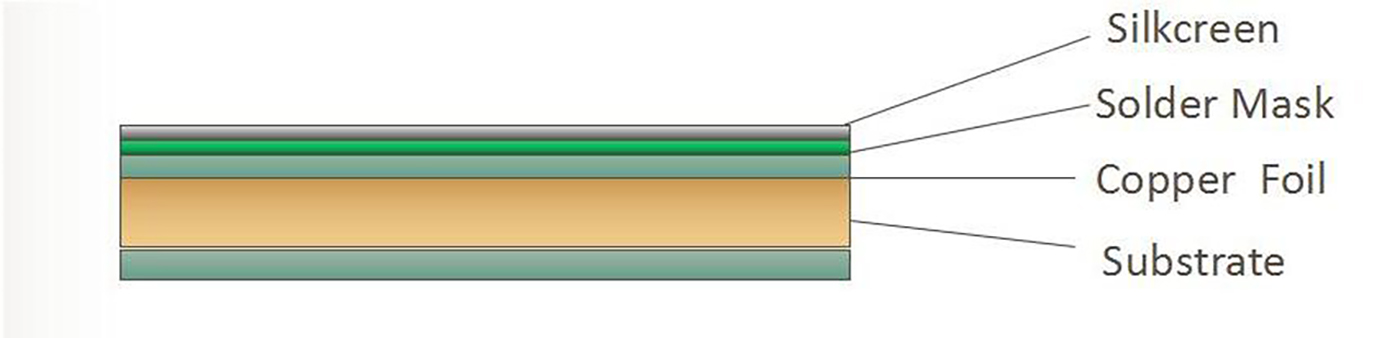

Ulwakhiwo lwePCB enamaleko amaninzi

Ii-PCB ze-Multilayer zandisa ngakumbi ukuntsonkotha kunye nokuxinana koyilo lwe-PCB ngokongeza umaleko ongezelelweyo ngaphaya kwamaleya aphezulu nasezantsi abonwa kwiibhodi ezimacala mabini.Ii-PCB ezininzi zakhiwe ngokulayita iileya ezahlukeneyo.Iibhodi zesekethe zangaphakathi, eziqhelekileyo ezinamacala amabini, zixutywe kunye, kunye neengqimba ezikhuselayo phakathi naphakathi kwe-copper-foil kwi-outer-layers.Imingxuma egrunjiweyo ngebhodi (nge-vias) iya kwenza unxibelelwano kunye neengqimba ezahlukeneyo zebhodi.

Ubuchwephesha kunye nokubanakho

Ibhodi yePCB Ibhodi yeSekethe ene-UL, SGS, ISO Certificates

Icala elinye, eliMbini kunye ne-PCB enamaleko amaninzi

UkuNgcwaba/Iimfama ngokuVias, iVia ngePad, iCounter Sink Hole, iScrew Hole(I-Counterbore), Cinezela-fit, iHalf Hole

I-HASL engenalo isikhokelo, iGolide yokuntywiliselwa/ iSilivere/iTin, i-OSP, iGold plating/umnwe, imaski e peelable

Iibhodi zeSekethe eziprintiweyo zibambelela kwi-IPC Class 2 & 3 ye-PCB yamazwe ngamazwe

Ubungakanani busukela kwiprototype ukuya kwimveliso yebhetshi ephakathi&enkulu

100% Uvavanyo lwe-E

| Into | Isakhono seMveliso |

| Umaleko ubala | 1-32 |

| Izinto eziphathekayo | FR-4, High TG FR-4, PTFE, Aluminium Base, Cu base, Rogers, Teflon, njl. |

| Ubungakanani obukhulu | 600mm X1200mm |

| Unyamezelo lolwandlalo lweBhodi | ±0.13mm |

| Ukutyeba kweBhodi | 0.20mm–8.00mm |

| Ukunyamezela ukutyeba(t≥0.8mm) | ±10% |

| Ukutyeba kweTolerancc(t<0.8mm) | ±0.1mm |

| I-Insulation Layer Thickncss | 0.075mm–5.00mm |

| Ubuncinci Iine | 0.075mm |

| Ubuncinci besithuba | 0.075mm |

| Out Layer Copper Ukutyeba | 18um-350um |

| Ngaphakathi Layer Copper Ukutyeba | 17um-175um |

| Umngxuma woKwemba (Oomatshini) | 0.15mm–6.35mm |

| Gqiba umngxuma (Mechanical) | 0.10mm–6.30mm |

| Ukunyamezelwa kweDiameter(Mechanical) | 0.05mm |

| Ubhaliso(oomatshini) | 0.075mm |

| Aspecl Umlinganiselo | 16:01 |

| Uhlobo lweMaski yeSolder | LPI |

| SMT Mini.Solder Mask Ububanzi | 0.075mm |

| Mini.Solder Mask Clearance | 0.05mm |

| I-Plag Hole Diameter | 0.25mm–0.60mm |

| Ukunyamezelwa koLawulo lwe-Impedans | 10% |

| Umphezulu Gqiba | HASL/HASL-LF, ENIG, iTin yokuntywiliselwa/iSilver, iFlash Gold, iOSP, umnwe weGolide, iGolide eNqinileyo |

Zivela phi izinto ze-resin kwi-ABIS?

Uninzi lwabo luvela kwi-Shengyi Technology Co., Ltd. (SYTECH), oye waba ngumvelisi wesibini we-CCL omkhulu wehlabathi ngokwexabiso lokuthengisa, ukusuka kwi-2013 ukuya kwi-2017. Saseka ubudlelwane bexesha elide lentsebenziswano ukususela ngo-2006. I-FR4 resin material (Imodeli ye-S1000-2, i-S1141, i-S1165, i-S1600) isetyenziselwa ukwenza iibhodi zeesekethe eziprintiweyo ezizimeleyo kunye namacala amabini kunye neebhodi ezininzi.Nazi iinkcukacha eziza kubhekisa kwireferensi yakho.

Kwi-FR-4: I-Sheng Yi, iBhodi yoKumkani, i-Nan Ya, i-Polycard, i-ITEQ, i-ISOLA

Kwi-CEM-1 kunye ne-CEM 3: iSheng Yi, iBhodi yoKumkani

Ngamaxesha amaninzi: Sheng Yi

Kunyango lweUV: Tamura, Chang Xing ( * Umbala okhoyo: oluhlaza) ISolder yecala elinye

Ifoto yolwelo: Tao Yang, Nqana (iFilimu emanzi)

Chuan Yu ( * Iyafumanekaimibala: Mhlophe, Mhlophe, Mthubi, Omfusa, Obomvu, Oluhlaza, Oluhlaza, Mnyama)

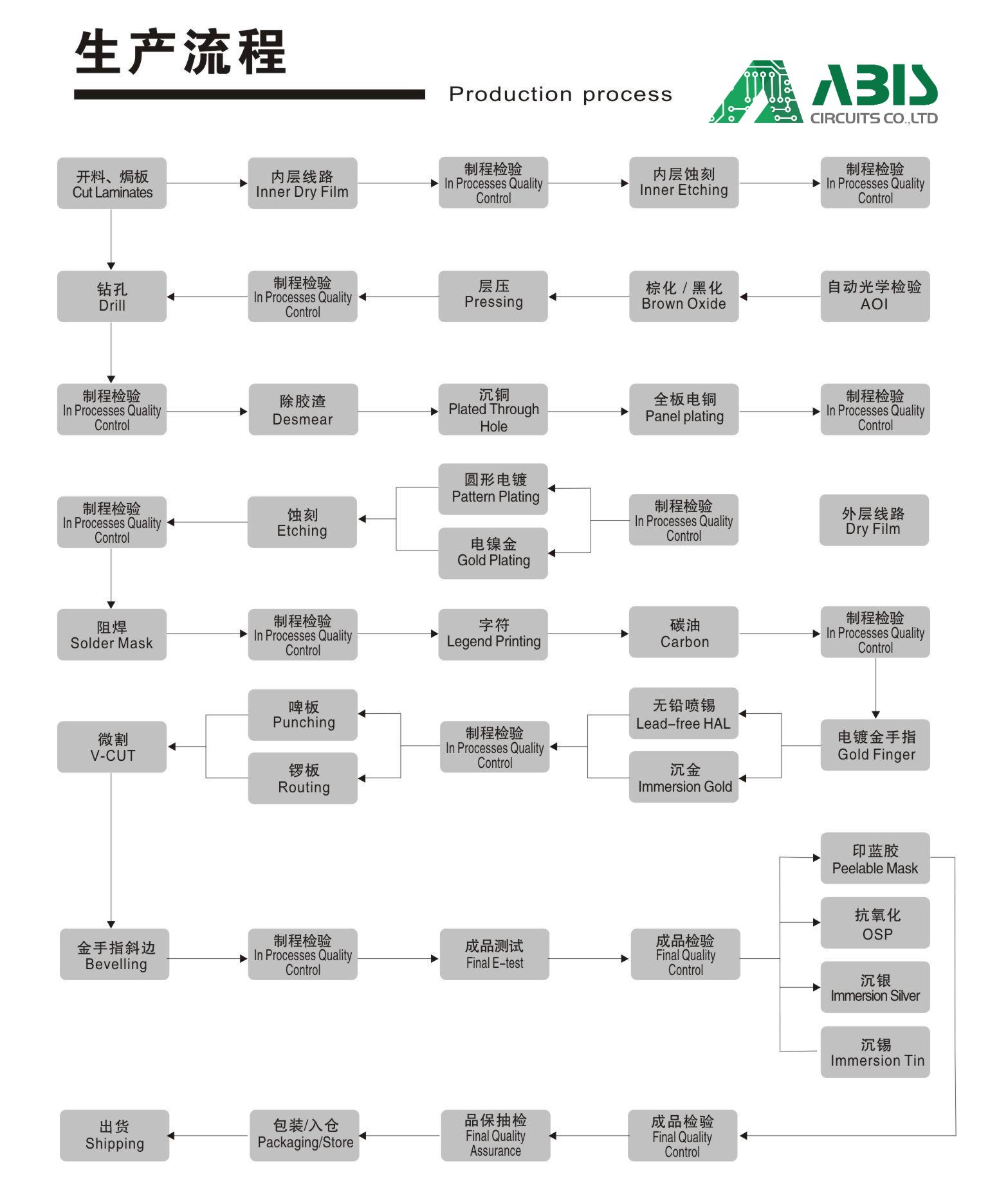

Inkqubo yeMveliso yePCB

Inkqubo iqala ngokuyila uYilo lwePCB usebenzisa nayiphi na isoftware yokuyila iPCB / isixhobo seCAD (iProteus, uKhozi, Okanye iCAD).

Onke amanye amanyathelo ngaweNkqubo yokuVelisa yeBhodi yeSekethe eShicileleyo eZingqongqo iyafana ne-Single Sided PCB okanye i-Double Sided PCB okanye i-Multi-layer PCB.

Q / T Ixesha lokukhokela

| Udidi | Ixesha lokukhokela elikhawulezayo | Ixesha eliqhelekileyo lokukhokela |

| Amacala amabini | Iiyure ezingama-24 | 120hrs |

| 4 Iileya | Iiyure ezingama-48 | 172hrs |

| 6 Iileya | 72hrs | 192hrs |

| 8 Iileya | Iiyure ezingama-96 | 212hrs |

| Iileya ezili-10 | 120hrs | iiyure ezingama-268 |

| 12 Iileya | 120hrs | 280hrs |

| 14 Iileya | Iiyure ezingama-144 | 292hrs |

| 16-20 Iileya | Kuxhomekeke kwiimfuno ezithile | |

| Ngaphezulu kwe20 Layers | Kuxhomekeke kwiimfuno ezithile | |

Intshukumo ye-ABIS yokulawula i-FR4 PCBS

Ukulungiswa komngxuma

Ukususa i-debris ngononophelo kunye nokulungelelanisa iiparamitha zoomatshini bokuqhuba: phambi kokucoca ngobhedu, i-ABIS ihlawula ingqalelo ephezulu kuyo yonke imingxuma kwi-FR4 PCB ephathwayo ukususa inkunkuma, izitenxo zomphezulu, kunye ne-epoxy smear, imingxuma ecocekileyo iqinisekisa ukuba iplating ibambelela ngempumelelo kwiindonga zomngxunya. .kwakhona, ekuqaleni kwenkqubo, iiparamitha zoomatshini bokuqhuba zihlengahlengiswa ngokuchanekileyo.

Ukulungiswa komphezulu

Ukuhlawula ngononophelo: abasebenzi bethu bezobuchwepheshe abanamava baya kuqaphela kwangaphambili ukuba ekuphela kwendlela yokuphepha umphumo ombi kukulindela imfuno yokuphathwa okukhethekileyo kunye nokuthatha amanyathelo afanelekileyo ukuqinisekisa ukuba inkqubo yenziwa ngononophelo nangokuchanekileyo.

Amazinga oKwandiswa kweThermal

Ukuqhelana nokujongana nezinto ezahlukeneyo, i-ABIS iya kukwazi ukuhlalutya ukudibanisa ukuze kuqinisekiswe ukuba kufanelekile.emva koko ukugcina ukuthembeka kwexesha elide le-CTE (i-coefficient yokwandiswa kwe-thermal), kunye ne-CTE ephantsi, i-CTE engaphantsi, into engenakwenzeka ukuba ifakwe kwimingxuma yokungaphumeleli ukuguquguquka okuphindaphindiweyo kobhedu okwenza udibaniso lwangaphakathi lwangaphakathi.

Ukukala

Ulawulo lwe-ABIS i-circuitry ihlaziywa ngeepesenti ezaziwayo ngokulindela le lahleko ukwenzela ukuba iileyile ziya kubuyela kwimilinganiselo yazo eyilelwe emva kokuba umjikelo we-lamination ugqityiwe.kwakhona, usebenzisa izindululo zokukalwa kwesiseko somenzi welaminate ngokudityaniswa nedatha yolawulo lwenkqubo yobalo lwangaphakathi, ukucofa imiba yesikali eya kuthi ihambelane ngokuhamba kwexesha ngaphakathi kuloo ndawo yokuvelisa.

Umatshini

Xa kufika ixesha lokwakha i-PCB yakho, i-ABIS qiniseka ukuba ukhetha inezixhobo ezifanelekileyo kunye namava okuyivelisa ngokuchanekileyo kwi-try yokuqala.

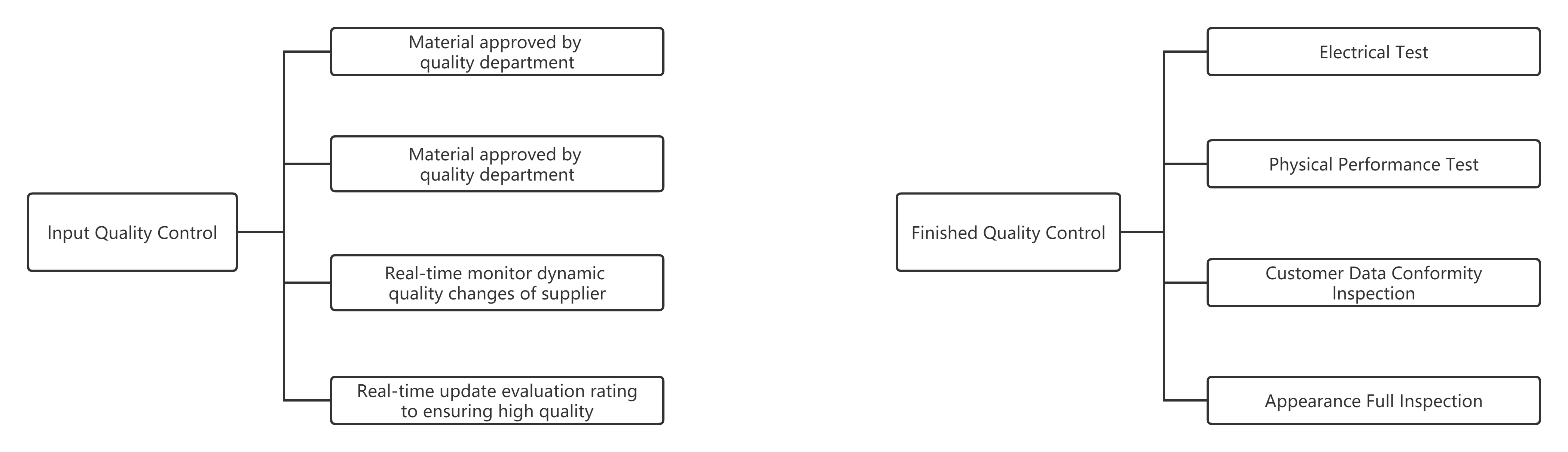

Umnqophiso woMgangatho we-ABIS

Ireyithi yokupasa kwezinto ezingenayo ngaphezu kwe-99.9%, inani lezinga lokulahlwa kobunzima lingaphantsi kwe-0.01%.

Amaziko aqinisekisiweyo e-ABIS alawula zonke iinkqubo eziphambili ukuphelisa yonke imiba enokubakho phambi kokuvelisa.

I-ABIS isebenzisa isoftware ephucukileyo ukwenza uhlalutyo olubanzi lwe-DFM kwidatha engenayo, kwaye isebenzisa iinkqubo zolawulo lomgangatho ophezulu kuyo yonke inkqubo yokwenziwa.

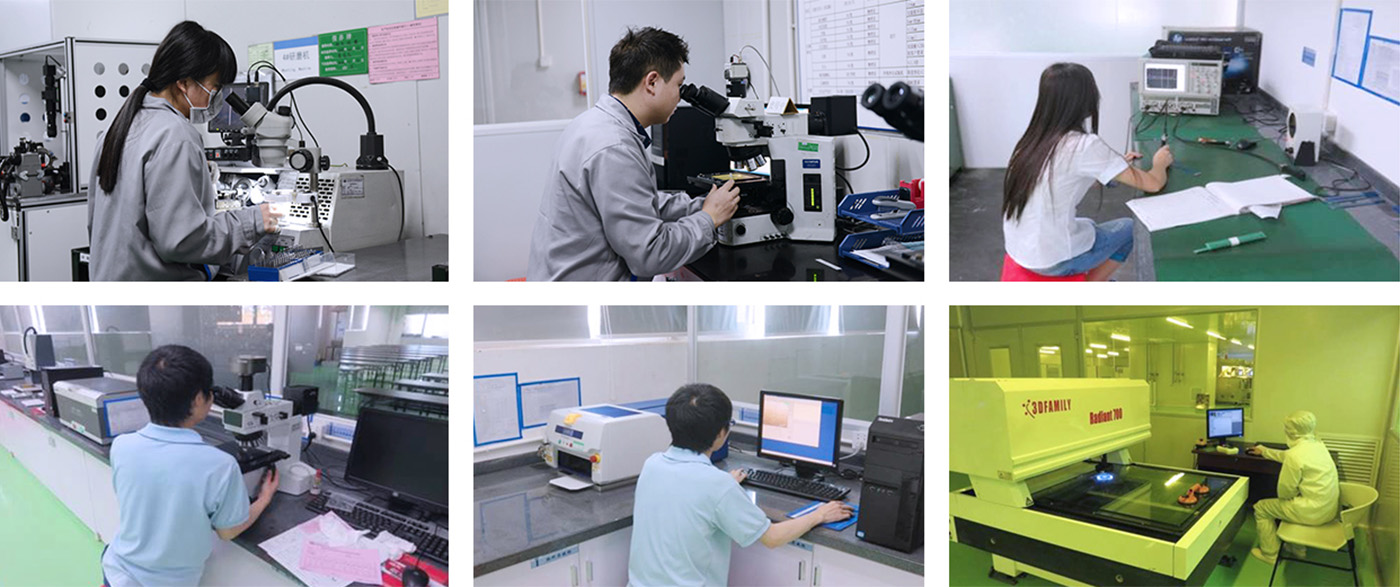

I-ABIS yenza i-100% yokuhlola okubonwayo kunye ne-AOI kunye nokwenza uvavanyo lombane, uvavanyo lombane ophezulu, uvavanyo lokulawula i-impedance, ulwahlulo lwe-micro-sectioning, uvavanyo lwe-thermal shock, uvavanyo lwe-solder, uvavanyo lokuthembeka, uvavanyo lokuxhathisa kunye novavanyo lwe-ionic yococeko.

Isatifikethi

Zeziphi iingenelo zokwenziwa kwemveliso kwi-ABIS?

Jonga ngeenxa zonke kuwe.Iimveliso ezininzi zivela eTshayina.Ngokucacileyo, oku kunezizathu ezininzi.Ayisekho nje ngexabiso.

Ukulungiselela izicatshulwa kwenziwa ngokukhawuleza.

Ii-odolo zemveliso zigqitywa ngokukhawuleza.Unokuzicwangcisa iiodolo ezicwangciselwe iinyanga kwangaphambili, sinokuzilungiselela ngokukhawuleza nje ukuba i-PO iqinisekisiwe.

Ikhonkco lonikezelo landiswa kakhulu.Yiyo loo nto sinokuthenga lonke icandelo kwiqabane elikhethekileyo ngokukhawuleza.

Abasebenzi abaguquguqukayo nabanomdla.Ngenxa yoko, samkela yonke iodolo.

Inkonzo ye-intanethi ye-24 kwiimfuno ezingxamisekileyo.Iiyure zokusebenza ze +10 iiyure ngosuku.

Iindleko eziphantsi.Akukho xabiso lifihliweyo.Yonga kubasebenzi, i-overhead kunye namalungiselelo.

FAQ

Ukuqinisekisa isicatshulwa esichanekileyo, qiniseka ukuba ubandakanya ulwazi olulandelayo lweprojekthi yakho:

Gqibezela iifayile zeGERBER kuquka noluhlu lweBOM

l Ubungakanani

l Ixesha lokuvula

l IiMfuno zephaneli

l Iimfuno zeMathiriyeli

l Gqibezela iimfuno

l Isicatshulwa sakho esiqhelekileyo siya kuhanjiswa kwiiyure nje ze-2-24, kuxhomekeke kubunzima boyilo.

Ihlolwe kwiiyure ezili-12.Nje ukuba umbuzo weNjineli kunye nefayile yokusebenza ihlolwe, siya kuqalisa imveliso.

ISO9001, ISO14001,UL USA&USA Canada,IFA16949, SGS, RoHS ingxelo.

IiNkqubo zethu zokuqinisekisa uMgangatho zingezantsi:

a), uHlolo oluBonakalayo

b), iFlying probe, isixhobo sokulungisa

c), Ulawulo lokuphazamiseka

d), ukubonwa kobuchule bomthengisi

e), imakroskopu yedijithali ye-metallo yegrafikhi

f), i-AOI (Uhlolo oluSebenzayo oluSebenzayo)

Ewe, siyavuya ukubonelela ngeesampulu zemodyuli ukuvavanya kwaye ujonge umgangatho, iodolo yesampulu exutyiweyo iyafumaneka.Nceda uqaphele ukuba umthengi kufuneka ahlawule iindleko zokuthumela.

Ngexesha lokuhanjiswa kwexesha lingaphezulu kwe-95%

a), iiyure ezingama-24 zijika ngokukhawuleza kwicala eliphindwe kabini leprototype PCB

b), iiyure ezingama-48 ze-4-8 umaleko weprototype PCB

c), iyure e-1 yekoteyishini

d), iiyure ezi-2 zombuzo wenjineli/ingxelo yesikhalazo

e), iiyure ze-7-24 zenkxaso yobugcisa / inkonzo ye-odolo / imisebenzi yokuvelisa

I-ABlS yenza i-100% yokuhlola okubonwayo kunye ne-AOl kunye nokwenza uvavanyo lombane, uvavanyo lombane ophezulu, uvavanyo lokulawula i-impedance, i-micro-sectioning, uvavanyo lwe-thermal shock, uvavanyo lwe-solder, uvavanyo lokuthembeka, uvavanyo lwe-insulating resistance, uvavanyo lokucoceka kwe-ionic kunye novavanyo olusebenzayo lwe-PCBA.

a), iyure e-1 yocaphulo

b), iiyure ezi-2 zengxelo yesikhalazo

c), 7*24 iyure inkxaso yobugcisa

d), 7*24 inkonzo ye-odolo

e), 7 * 24 ukuhanjiswa kweyure

f), 7*24 imveliso run

Amashishini angundoqo e-ABIS: Ulawulo lwezoShishino, ezoNxibelelwano ngoNxibelelwano, iiMveliso zeeMoto kunye nezoNyango.IMarike ePhambili ye-ABIS: 90% iMarike yaMazwe ngaMazwe (40% -50% yase-USA, i-35% yaseYurophu, i-5% yaseRashiya kunye ne-5% -10% ye-East Asia) kunye ne-10% yeMarike yasekhaya.